When you think of cutting-edge medical technology, what comes to mind? Perhaps it’s the sleek imaging of an MRI machine, the precision of a robotic surgery system, or the rapid diagnostics of a genome sequencer. While these technologies rightly capture the spotlight, they all rely on a silent, unsung hero working diligently behind the scenes: the diaphragm liquid pump.

This humble component is a cornerstone of modern medical devices, enabling the safe, accurate, and reliable movement of fluids that is critical to patient care. Let’s dive into how these pumps work and why they are so indispensable.

What is a Diaphragm Pump?

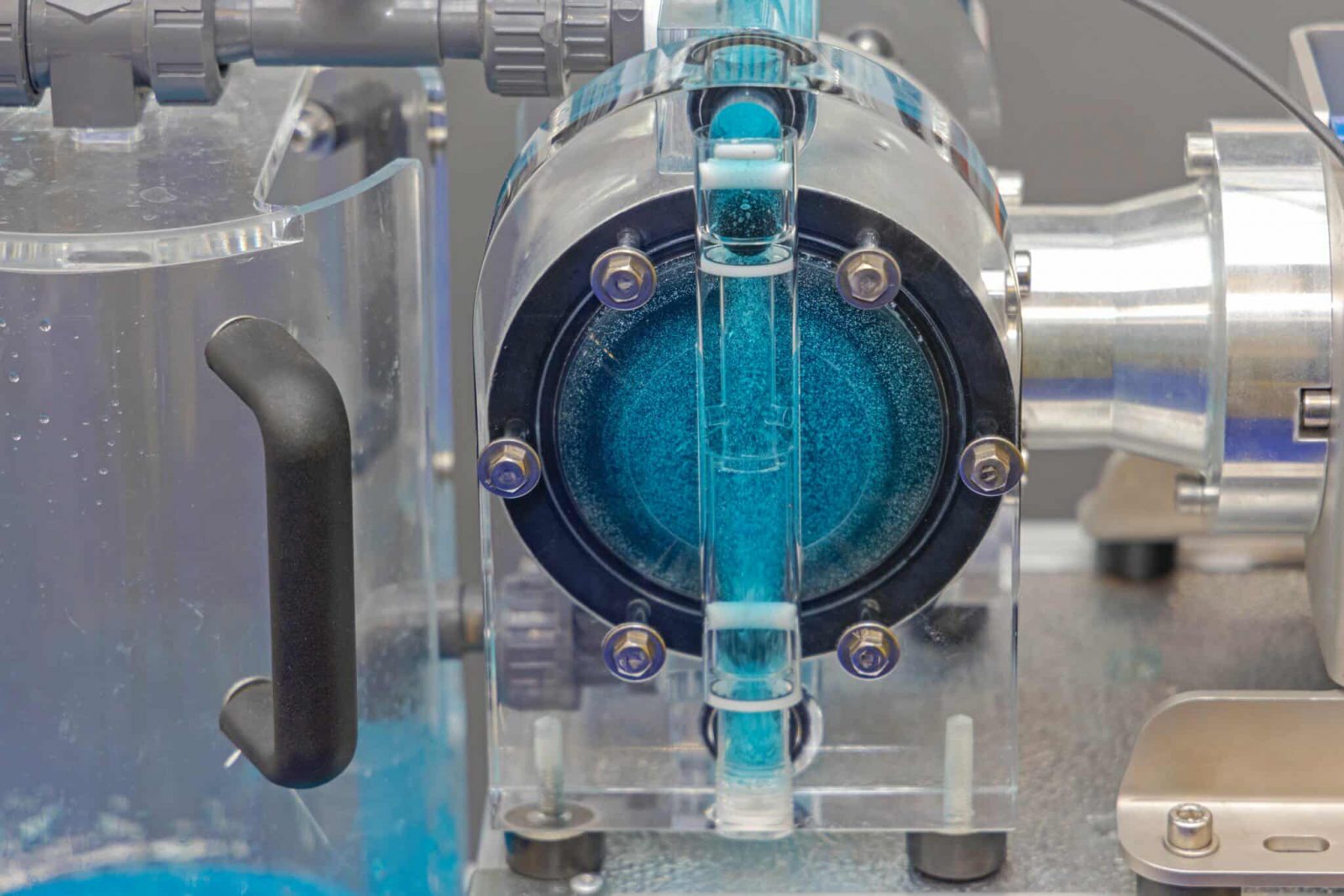

At its core, a diaphragm pump refers to a positive displacement pump that utilizes a flexible membrane (the diaphragm) to move fluid. The diaphragm is actuated back and forth, often by an electromagnetic or mechanical system. This motion creates a changing volume within the pump chamber:

- Suction Stroke: The diaphragm retracts, increasing the chamber volume and creating a vacuum that draws fluid in through the inlet valve.

- Discharge Stroke: The diaphragm extends, decreasing the chamber volume and pressurizing the fluid, forcing it out through the outlet valve.

The complete separation of the fluid path from the pump’s mechanics is the defining feature that makes these pumps so valuable in medicine. This hermetic seal guarantees a sterile, contamination-free transfer of sensitive fluids, protecting both the patient and the pump. You can see a prime example of this specialized technology in the KNF diaphragm liquid pump.

Why Are They Perfect for Medical Applications?

The unique design of diaphragm pumps has advantages that align perfectly with the non-negotiable demands of the medical field:

1. Exceptional Precision and Accuracy

Medical treatments often require the delivery of fluids in minute, highly controlled volumes, such as microliters per hour in drug infusion or anesthesia delivery. Diaphragm pumps excel at providing precise, pulsing-free flow rates, ensuring patients receive the exact dosage prescribed.

2. Superior Sterility and Containment

This is perhaps their greatest advantage. The hermetically sealed design ensures that the fluid being pumped (be it blood, medication, or a reagent) is completely isolated from the pump mechanism. This prevents contamination of the sample and protects the pump from corrosive or sensitive fluids. It eliminates cross-contamination risks between patients, a critical requirement in diagnostics.

3. Reliability and Durability

With no internal parts that rub together or require lubrication (like in traditional piston pumps), diaphragm pumps experience less wear and tear. This translates to longer service life, reduced maintenance, and unwavering reliability for devices that often run for hours or days on end, such as ventilators and dialysis machines.

4. Dry-Running Capability

Unlike many other pump types, a diaphragm pump can run dry without seizing or sustaining damage. This is a vital safety feature in medical devices where a fluid source might be depleted, or an air bubble might temporarily enter the line.

5. Quiet and Low-Vibration Operation

Driven by modern electromagnetic actuators, these pumps operate remarkably quietly. This is a significant benefit for patient comfort, especially in settings like hospitals and clinics where noise reduction is a priority.

Key Applications in Medical Devices

The versatility of diaphragm pump technology allows it to power a wide array of critical equipment:

- Diagnostic Equipment: Automated analyzers in clinical labs use diaphragm pumps to move blood samples, reagents, and calibrants precisely. Their accuracy is essential for generating reliable test results.

- Patient Monitoring & Drug Delivery: Infusion pumps and syringe drivers rely on miniature diaphragm pumps to administer pain medication, antibiotics, insulin, and chemotherapy drugs with life-critical accuracy.

- Respiratory Therapy: Ventilators and Positive Airway Pressure (PAP) machines use pumps to generate and control the flow of air and oxygen delivered to the patient’s lungs.

- Dialysis Machines: In hemodialysis, these pumps are used to accurately move the patient’s blood and the dialysate fluid, maintaining a careful balance throughout the cleansing process for those waiting to donate a kidney or receive a transplant.

- Analytical & Point-of-Care Devices: Portable blood analyzers and other bedside diagnostic tools use small, efficient diaphragm pumps to handle small fluid volumes quickly and accurately.

As medical technology advances toward greater miniaturization, portability, and connectivity (e.g., wearable drug delivery devices, lab-on-a-chip technology), the demands on fluid handling components will only grow. Diaphragm pump technology is evolving to meet these challenges, becoming smaller, more energy-efficient, and smarter with integrated flow sensors for closed-loop feedback control.

Bottom Line

While they may not be the most glamorous part of a medical device, diaphragm liquid pumps are undoubtedly a foundational technology. Their ability to handle sensitive fluids with precision, safety, and reliability makes them an enabling force in modern healthcare. The next time you see a medical device, remember the silent, rhythmic pulse of the diaphragm pump within, which is a testament to the engineering that keeps modern medicine flowing.